Wiring RTDs: 2-Wire vs 3-Wire vs 4-Wire – Which to Use When

What Are RTDs and Why Does Wiring Matter?

A Resistance Temperature Detector (RTD) is a precision temperature sensor made from a metal (typically platinum) whose electrical resistance changes predictably with temperaturethermonicindia.com. RTDs offer high stability and accuracy, making them ideal for industrial applications that demand precise temperature controlthermonicindia.com. However, the way an RTD is wired – using 2, 3, or 4 leads – has a big impact on measurement accuracy. Long leads and extra resistance in the wiring can introduce errors in the temperature readingdwyeromega.com. Understanding these wiring schemes helps engineers choose the right RTD setup for each application.

2-Wire RTDs: Simple but Least Accurate

The simple two-wire RTD has one lead attached to each end of the sensing element. A 2-wire RTD is the most basic configuration. It connects the RTD element to the instrument with just two wires – one to each end of the sensor. This simplicity keeps costs low, but it also means the resistance of the leads is included in the measurement.

In other words, any resistance in the wiring adds to the RTD’s resistance, causing a temperature reading error especially when the cable run is longdwyeromega.com. For this reason, 2-wire RTDs are generally used only for very short distances or non-critical monitoring where a few degrees of error are acceptabledwyeromega.comncd.io. In most industrial controls, a 2-wire RTD is chosen only when cost is critical and the loss of accuracy can be toleratedncd.io.

3-Wire RTDs: Industrial Standard Balance

The 3-wire RTD adds a third lead to help cancel out lead resistance. A 3-wire RTD is the most common wiring in industrial systems. It uses three conductors: two wires to one end of the RTD element and one wire to the other end.

This extra wire allows the measurement instrument to compensate for most of the lead resistance. In practice, the transmitter measures the combined resistance of two leads plus the RTD, then subtracts the resistance of the pair of leads alone, effectively canceling out the lead wiresncd.io.

This assumes all three leads have identical resistance (same material and length). When this condition is met, the 3-wire RTD removes nearly all the error that plagued the 2-wire setupncd.iodwyeromega.com. The result is significantly improved accuracy, with only minor residual error if the lead resistances are slightly unequal. In short, 3-wire RTDs strike a practical balance: they are much more accurate than 2-wire (because most lead resistance is compensated) but do not require the extra complexity of 4-wire cablingncd.ioncd.io. This is why 3-wire RTDs are the industrial default for most process control applicationsncd.ioncd.io.

4-Wire RTDs: Maximum Precisio

Two wires carry the excitation current and two sense the voltage, eliminating lead resistance errors. A 4-wire RTD provides the highest accuracy by completely eliminating lead resistance from the measurement. In this configuration, there are four separate conductors: two carry a known excitation current through the RTD element, and two measure the voltage drop across the RTDncd.io.

Because the voltage-sensing wires draw negligible current, any resistance they have does not affect the voltage measurement. As a result, the calculated resistance is purely that of the RTD itself, with no contribution from the lead wiresncd.iodwyeromega.com. This scheme yields the most precise and repeatable temperature readings, which is why 4-wire RTDs are preferred in high-precision laboratories, calibration systems, and critical industrial loops where even small errors are unacceptablencd.iodwyeromega.com. The trade-offs are higher complexity and cost – four wires and often a more sophisticated transmitter – but for demanding applications the accuracy gain is worth itncd.io.

Choosing the Right RTD Wiring

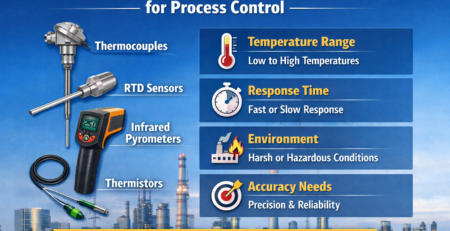

Selecting the ideal wiring scheme depends on the application’s accuracy requirements, wire run length, and budgetdwyeromega.comncd.io. In summaryncd.io:

- 2-Wire RTDs: Best for short, low-cost runs where precision is not crucialncd.io. Use 2-wire in small machines, low-end HVAC or basic monitoring where a few degrees off is acceptable.

- 3-Wire RTDs: The workhorse of industry. Use 3-wire in most plant-floor and process-control loops for a good balance of accuracy and costncd.ioncd.io. It compensates lead resistance under normal conditions, making it suitable for medium-length runs in factories, refineries, and HVAC systems.

- 4-Wire RTDs: Used only when maximum accuracy is needed (for example, precision furnaces, lab equipment, or very long cable runs). 4-wire completely cancels all lead resistancedwyeromega.com, so it’s ideal for calibration standards or critical processes. Note that 4-wire setups are more expensive and require matching transmitter instruments.

Thermonic RTD Solutions and Next Steps

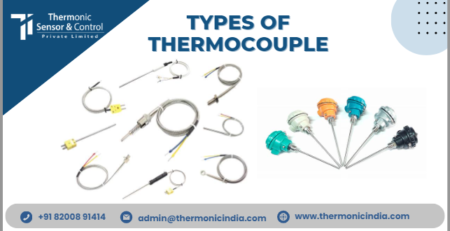

Thermonic Sensor & Control offers a full line of industrial RTD products and accessories to suit every scenario. Our catalog includes high-quality PT100/PT1000 sensors (head-mounted, immersion, flange, etc.) with options for 2-, 3-, or 4-wire connectionsthermonicindia.com. For hazardous environments, we supply flameproof RTD probes with explosion-proof headsthermonicindia.com.

We also offer robust RTD cabling (fiberglass-insulated, stainless-steel braided, teflon, PVC, etc.) that withstands high temperatures, abrasion, and EMI/RFI noisethermonicindia.comthermonicindia.com. For long-distance or loop-powered installations, pair an RTD with one of Thermonic’s 4-20mA temperature transmitters to get an isolated, industry-standard signalthermonicindia.com.

Leave a Reply