The Complete Guide to Temperature and Pressure Sensors

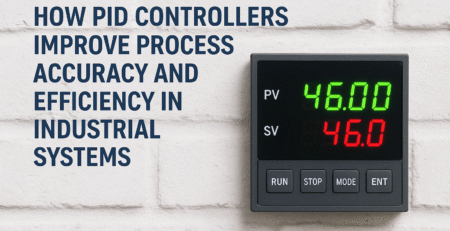

Temperature and pressure are two of the most critical parameters in industrial operations. Whether it’s monitoring a chemical reaction, ensuring safe boiler operations, or controlling HVAC systems, accurate sensing is the foundation of efficiency, safety, and compliance.

At Thermonic Sensor and Control Pvt. Ltd., we specialize in delivering reliable temperature and pressure sensors that meet the diverse needs of industries worldwide.

1. What Are Temperature and Pressure Sensors?

- Temperature Sensors: Devices

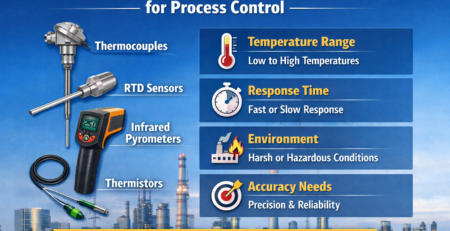

2. Types of Temperature Sensors

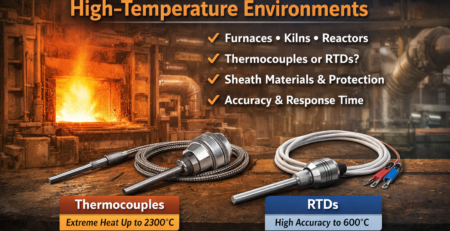

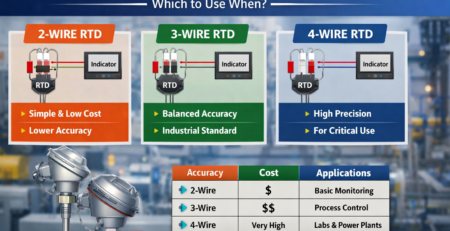

- RTDs (Resistance Temperature Detectors): High accuracy, long-term stability.

- Thermocouples: Wide temperature ranges, cost-effective.

- Infrared Sensors: Non-contact, ideal for moving/fragile objects.

- Thermistors: Compact, fast response, limited range.

- Absolute Pressure Sensors: Measure relative to a vacuum.

- Gauge Pressure Sensors: Measure relative to atmospheric pressure.

- Differential Pressure Sensors: Compare pressure between two points.

- Sealed Pressure Sensors: Calibrated against a fixed pressure reference.

- Automotive: Engine monitoring, tire pressure, exhaust control.

- Pharmaceuticals: Cleanroom monitoring, sterilization, packaging.

- HVAC Systems: Airflow, ventilation, and energy efficiency.

- Oil & Gas: Pipeline safety, refinery operations.

- Food & Beverage: Process consistency and safety.

5. Benefits of Using the Right Sensor

- Improved accuracy and reliability.

- Reduced downtime and predictive maintenance.

- Enhanced compliance with safety and quality standards.

- Energy savings and process optimization.

6. Why Choose Thermonic Sensors?

- Built with robust designs for industrial durability.

- Custom-engineered solutions to match unique requirements.

- Seamless integration with automation and IoT platforms.

- Backed by technical expertise and responsive support.

Leave a Reply