Smart Temperature Control Systems for Textile Manufacturing Excellence

Introduction

In today’s highly competitive textile industry, temperature control is no longer optional—it’s mission-critical. From fiber processing and dyeing to finishing and packaging, precise temperature regulation directly influences fabric quality, process efficiency, energy consumption, and operational consistency.

This is where smart temperature control systems step in—enabling textile manufacturers to move from reactive monitoring to data-driven, automated process optimization.

Why Temperature Control Is Critical in Textile Manufacturing

Textile processes are extremely sensitive to temperature variations. Even minor deviations can lead to:

- Uneven dye absorption

- Fabric shrinkage or deformation

- Reduced yarn strength

- Higher rejection and rework rates

Processes such as spinning, weaving, dyeing, drying, and heat-setting require stable and repeatable temperature conditions to maintain product quality and meet customer specifications.

What Are Smart Temperature Control Systems?

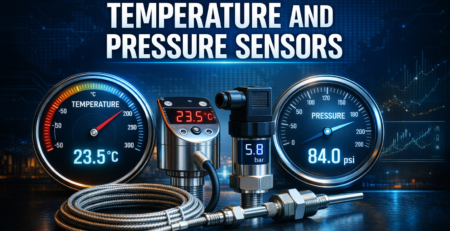

A smart temperature control system integrates:

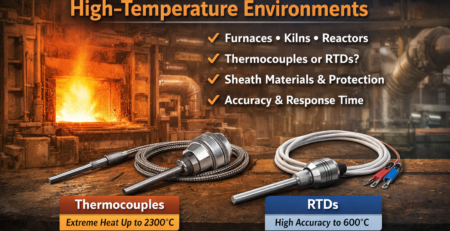

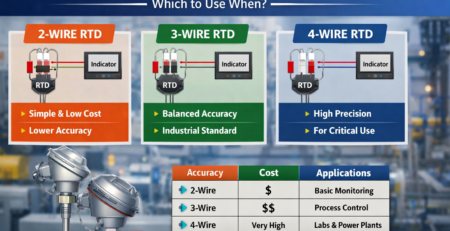

- RTD temperature sensors (PT100 / PT1000)

- Temperature transmitters

- Digital temperature controllers

- PLC / SCADA connectivity

These systems continuously monitor temperature, analyze real-time data, and automatically adjust heating or cooling mechanisms to maintain optimal conditions—without manual intervention.

Key Components Used in Textile Temperature Control

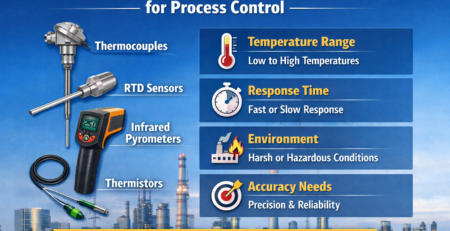

1. RTD Temperature Sensors

RTDs offer high accuracy, stability, and repeatability, making them ideal for textile environments where consistent readings are essential. They are commonly used in dyeing machines, dryers, boilers, and heat chambers.

2. Temperature Transmitters

Transmitters convert sensor signals into standard 4–20 mA outputs, ensuring reliable long-distance signal transmission with minimal noise—perfect for large textile plants.

3. Temperature Controllers

Digital temperature controllers regulate heaters, blowers, or steam valves based on predefined setpoints, ensuring tight temperature control across processes.

Benefits of Smart Temperature Control in Textile Plants

✔ Improved Fabric Quality

Consistent temperature ensures uniform dyeing, reduced defects, and superior finish quality.

✔ Energy Efficiency

Automated control reduces overheating and unnecessary energy consumption, leading to lower operational costs.

✔ Reduced Downtime

Real-time monitoring and alarms help identify deviations early, preventing machine damage and unplanned shutdowns.

✔ Process Automation

Integration with PLC and SCADA systems enables centralized monitoring and smarter decision-making.

✔ Compliance & Consistency

Helps meet quality standards, audits, and customer expectations with documented process data.

Applications in the Textile Industry

Smart temperature control systems are widely used in:

- Dyeing and bleaching machines

- Stenters and drying chambers

- Boilers and steam lines

- Heat-setting and curing ovens

- Climate control in spinning and weaving areas

Leave a Reply