Cold Junction Compensation in Thermocouples

In Cold Junction Compensation (CJC) becomes a strategic enabler rather than just a technical feature.

In modern industrial environments, accurate temperature measurement is mission-critical for process efficiency, safety, and product quality. Thermocouple sensors are widely used due to their durability and wide temperature range. However, without a proper reference point, even the most advanced thermocouple can deliver misleading data.

In this blog, we’ll deep-dive into what Cold Junction Compensation is, why it matters, and how it improves thermocouple accuracy across industrial applications.

What is Cold Junction Compensation?

Cold Junction Compensation (CJC) is a technique used in thermocouple temperature measurement to correct inaccuracies caused by changes in ambient temperature at the reference junction.

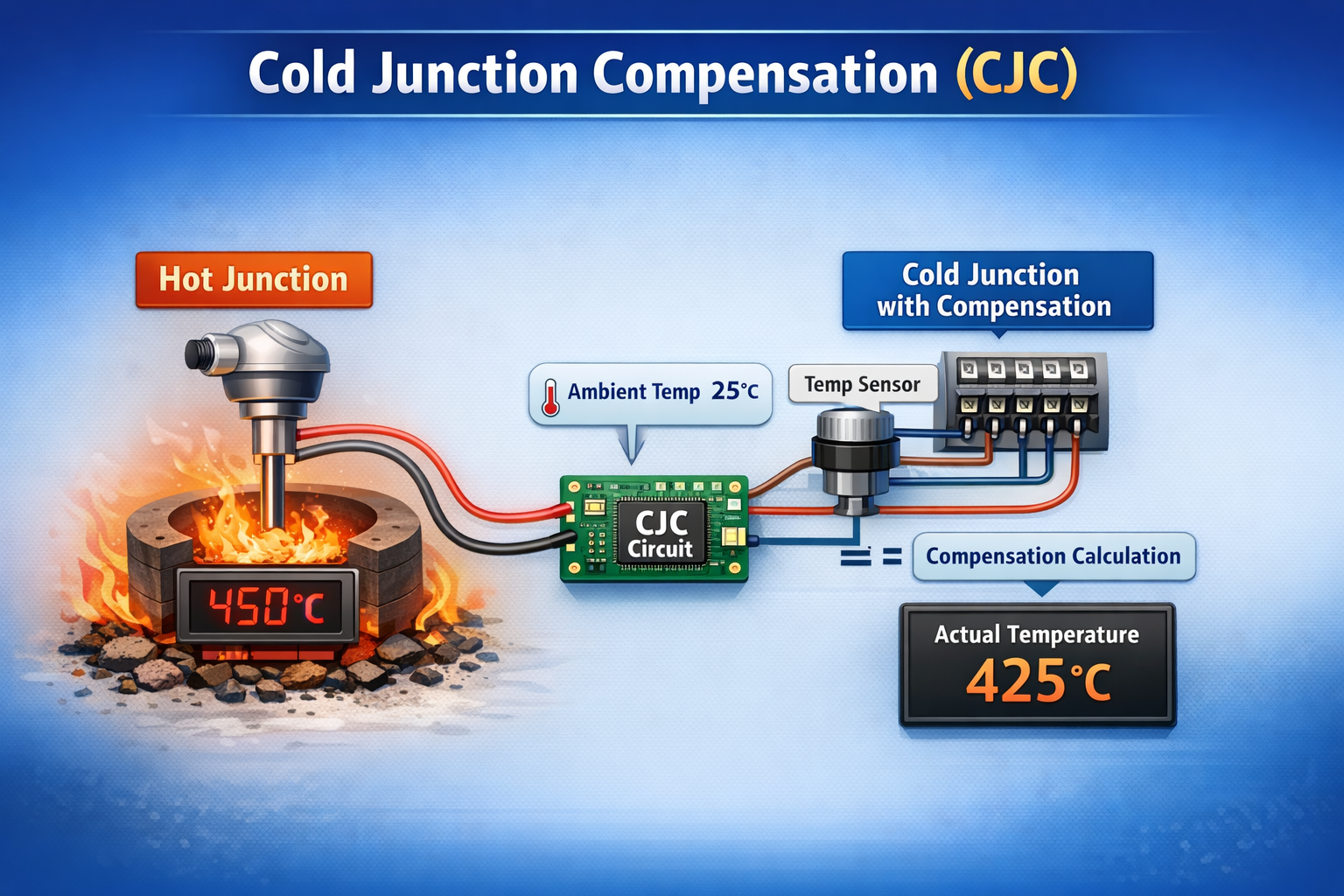

A thermocouple generates a voltage based on the temperature difference between two junctions:

- Hot Junction – the sensing point exposed to the process temperature

- Cold Junction – the reference point where the thermocouple wires connect to measuring instruments

Standard thermocouple tables assume the cold junction is maintained at 0°C, which is unrealistic in real-world installations. CJC compensates for this deviation, ensuring the measured temperature reflects actual process conditions.

Why Cold Junction Compensation is Important

From an operational and commercial standpoint, ignoring CJC can result in:

- Incorrect temperature readings

- Process instability

- Increased scrap and rework

- Compliance and audit risks

By implementing Cold Junction Compensation, industries benefit from:

- High-accuracy temperature measurement

- Stable and repeatable process control

- Reduced recalibration costs

- Improved system reliability

In short, CJC protects the integrity of temperature data.

How Cold Junction Compensation Works

Cold Junction Compensation works by placing an auxiliary temperature sensor near the cold junction. This sensor measures the actual ambient temperature, and the system automatically applies a correction factor.

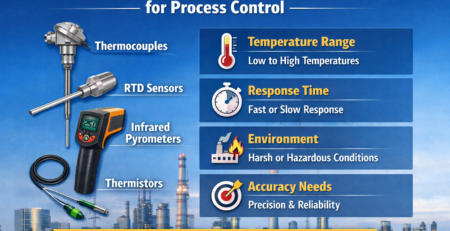

Commonly used CJC sensors include:

- Thermistors

- RTDs (Resistance Temperature Detectors)

- Integrated temperature sensing ICs

The measured cold junction temperature is added to the thermocouple voltage calculation, delivering a true and compensated temperature output.

Types of Cold Junction Compensation

Different industrial requirements call for different CJC approaches:

1. Thermistor-Based CJC

- Cost-effective

- Suitable for general industrial applications

- Moderate accuracy

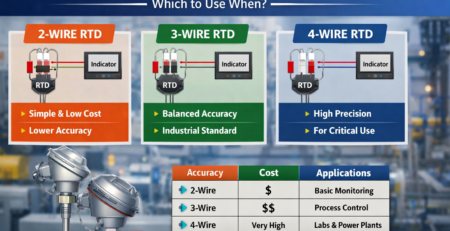

2. RTD-Based CJC

- High accuracy and stability

- Preferred in critical and regulated environments

3. IC-Based CJC

- Compact and digitally stable

- Ideal for modern transmitters and smart sensors

The selection depends on accuracy requirements, environmental conditions, and system architecture.

Applications of Cold Junction Compensation

Cold Junction Compensation is essential wherever thermocouples are used, including:

- Industrial furnaces and kilns

- Power plants

- HVAC systems

- Chemical and pharmaceutical processes

- Plastic and metal processing industries

Any application that relies on thermocouples cannot afford to overlook CJC.

Benefits of Using Cold Junction Compensation

From a business and engineering perspective, CJC delivers:

- Enhanced measurement accuracy

- Better control loop performance

- Reduced downtime

- Higher customer confidence

- Long-term operational efficiency

It transforms raw temperature sensing into decision-grade data.

Leave a Reply