Advanced industrial sensors for process stability

In today’s competitive manufacturing landscape, process stability is no longer just an operational concern—it’s a strategic priority. Frequent fluctuations, unplanned downtime, and inconsistent output directly impact productivity, quality, and profitability.

One of the most overlooked contributors to instability is outdated or inaccurate sensing technology. This case-based insight highlights how deploying advanced industrial sensors can significantly improve process stability and overall plant performance.

The Challenge: Inconsistent Readings and Process Variations

A mid-sized manufacturing facility operating under continuous process conditions was experiencing:

- Frequent process deviationshttps://thermonicindia.com/choosing-the-right-probe-for-extreme-heat/

- High rejection rates

- Reactive maintenance cycles

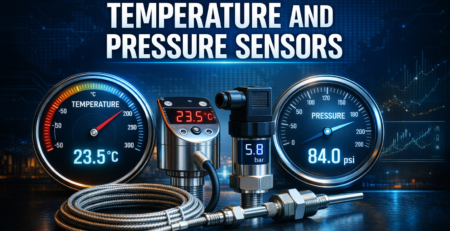

- Inconsistent temperature and pressure readings

Despite having automation in place, the plant lacked reliable, high-accuracy sensors, leading to delayed decision-making and operational inefficiencies.

The Root Cause: Legacy Sensors and Limited Visibility

Upon evaluation, it became clear that:

- Sensors were operating beyond calibration limits

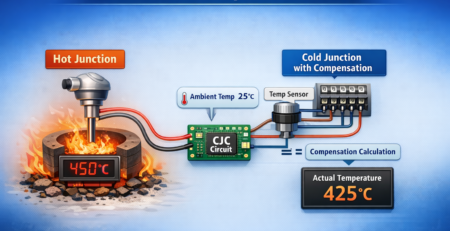

- Data accuracy was compromised in high-temperature zones

- Response time was slow during process fluctuations

This resulted in poor process visibility, making it difficult for operators to maintain consistent control parameters.

The Solution: Implementing Advanced Sensor Technology

The plant upgraded to advanced industrial sensors designed for harsh operating conditions, offering:

- Higher accuracy and repeatability

- Faster response time

- Improved durability in extreme environments

- Better compatibility with existing control systems

These sensors provided real-time, reliable data, enabling proactive process control instead of reactive troubleshooting.

The Impact: Measurable Improvement in Process Stability

Post-implementation, the facility observed:

- Significant reduction in process deviations

- Improved product consistency

- Lower maintenance intervention

- Enhanced operator confidence and control

By stabilizing critical parameters, the plant achieved better throughput and reduced operational risk—a clear example of how sensor quality directly influences business outcomes.

Why Advanced Sensors Matter More Than Ever

Modern manufacturing demands:

- Precision over approximation

- Predictive insights over reactive fixes

- Long-term reliability over short-term cost savings

Advanced sensors play a pivotal role in supporting Industry 4.0 initiatives, enabling smarter decisions, better compliance, and sustainable growth.

Stability Starts with the Right Measurement

Process stability doesn’t happen by chance—it starts with accurate measurement and intelligent sensing. Investing in the right sensor technology empowers manufacturers to optimize operations, reduce downtime, and stay competitive in an evolving industrial ecosystem.

Leave a Reply