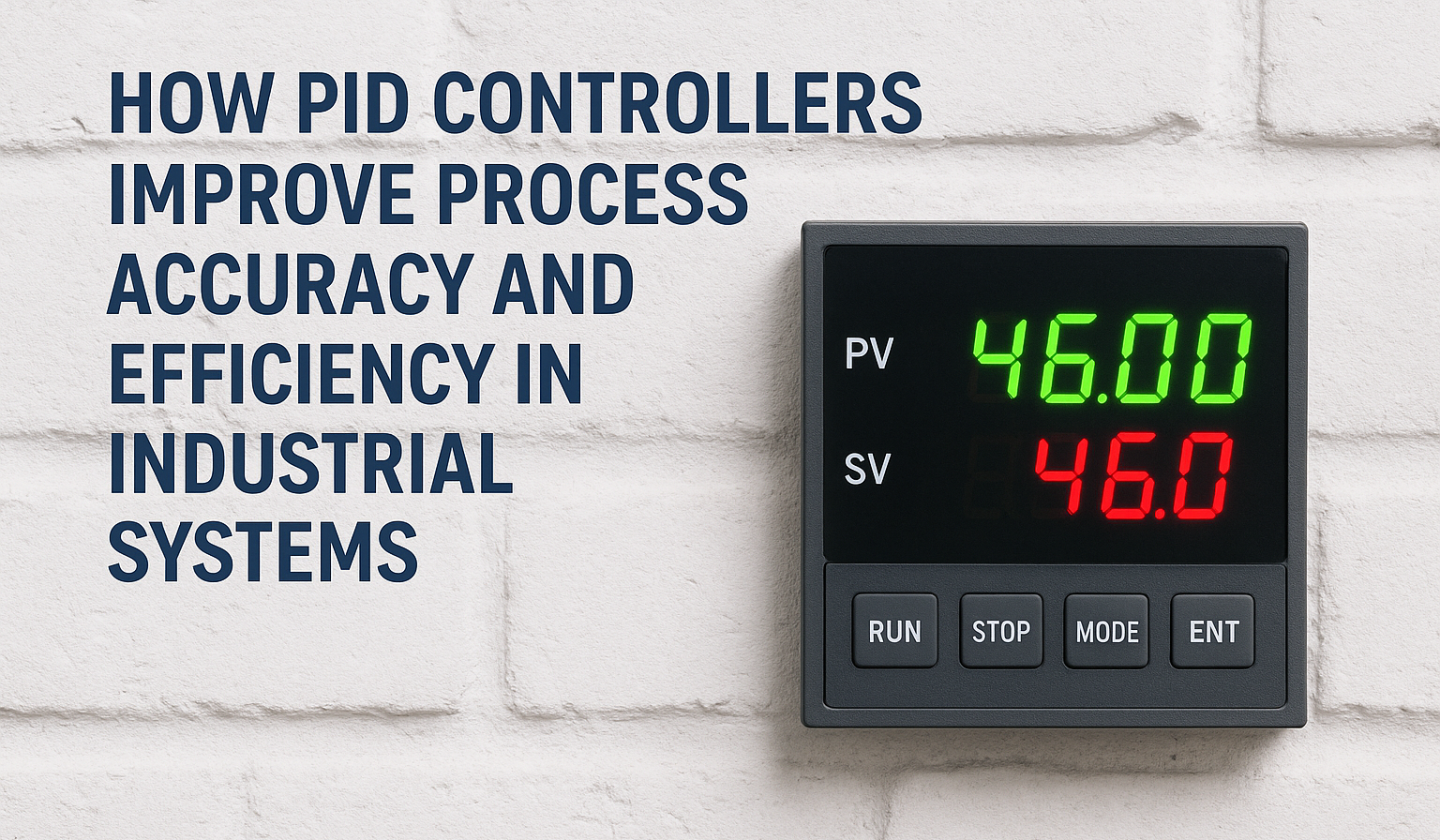

How PID Controllers Improve Process Accuracy and Efficiency in Industrial Systems

In the landscape of modern industrial automation, precision is the currency of competitiveness. Proportional–Integral–Derivative (PID) controllers are the backbone of process control across sectors — from chemical processing and food production to HVAC and power generation. At Thermonic Sensor and Control Pvt. Ltd., we design control solutions that don’t just regulate variables — they optimize outcomes, mitigate risk, and drive operational excellence.

Operational leaders often ask: Why invest in PID control when there are advanced algorithms and AI-based systems? The answer is simple and strategic — PID controllers deliver predictable, robust, and cost-effective control, especially in environments where stability, fast response, and proven reliability are non-negotiable.

Key business benefits:

- Reduced process variability → higher product yield and consistency.

- Faster settling times → minimized scrap and cycle-time improvements.

- Lower manual intervention → reduced OPEX and fewer human errors.

A PID controller continuously evaluates the difference between a process variable (e.g., temperature, pressure, flow) and its desired setpoint, then applies corrective action using three terms:

- Proportional (P): immediate correction proportional to current error.

- Integral (I): eliminates steady-state error by integrating past errors.

- Derivative (D): anticipates future error by observing the rate of change.

Leave a Reply