Advantages of RTD Sensors in Industrial Process Control

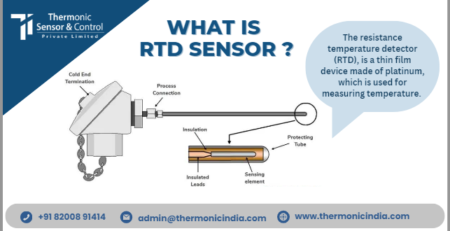

- RTD sensors, also known as Resistance Temperature Detectors, offer several significant advantages in industrial process control. These advanced temperature measurement devices have become integral components in various industries due to their precision and reliability.

- One of the key advantages of RTD sensors is their exceptional accuracy. They provide highly precise temperature measurements, ensuring that industrial processes operate within the desired temperature range. This accuracy is vital in industries where even a slight deviation can impact product quality, safety, or efficiency.

- Reliability is another crucial aspect of RTD sensors. They exhibit excellent stability and repeatability over time, making them ideal for long-term industrial process control. Their consistent performance allows for reliable monitoring and regulation of temperature, contributing to smoother operations and improved product quality.

- RTD sensors are also highly resistant to environmental factors, such as vibrations and electromagnetic interference, which can affect measurement accuracy. This resilience makes them suitable for use in demanding industrial environments where robustness is essential.

- Furthermore, RTD sensors offer a wide temperature range, allowing for precise monitoring in both high and low-temperature applications. They can handle extreme temperatures and maintain accuracy, making them versatile solutions for diverse industrial processes.

- In addition to their accuracy, reliability, and temperature range, RTD sensors are compatible with various control systems and can easily integrate into existing industrial setups. This compatibility ensures seamless integration into process control systems, facilitating efficient monitoring and regulation.

Overall, the advantages of RTD sensors in industrial process control are clear. Their accuracy, reliability, temperature range, and compatibility make them indispensable tools for optimizing processes, enhancing operational performance, and ensuring product quality in a wide range of industries.

Leave a Reply