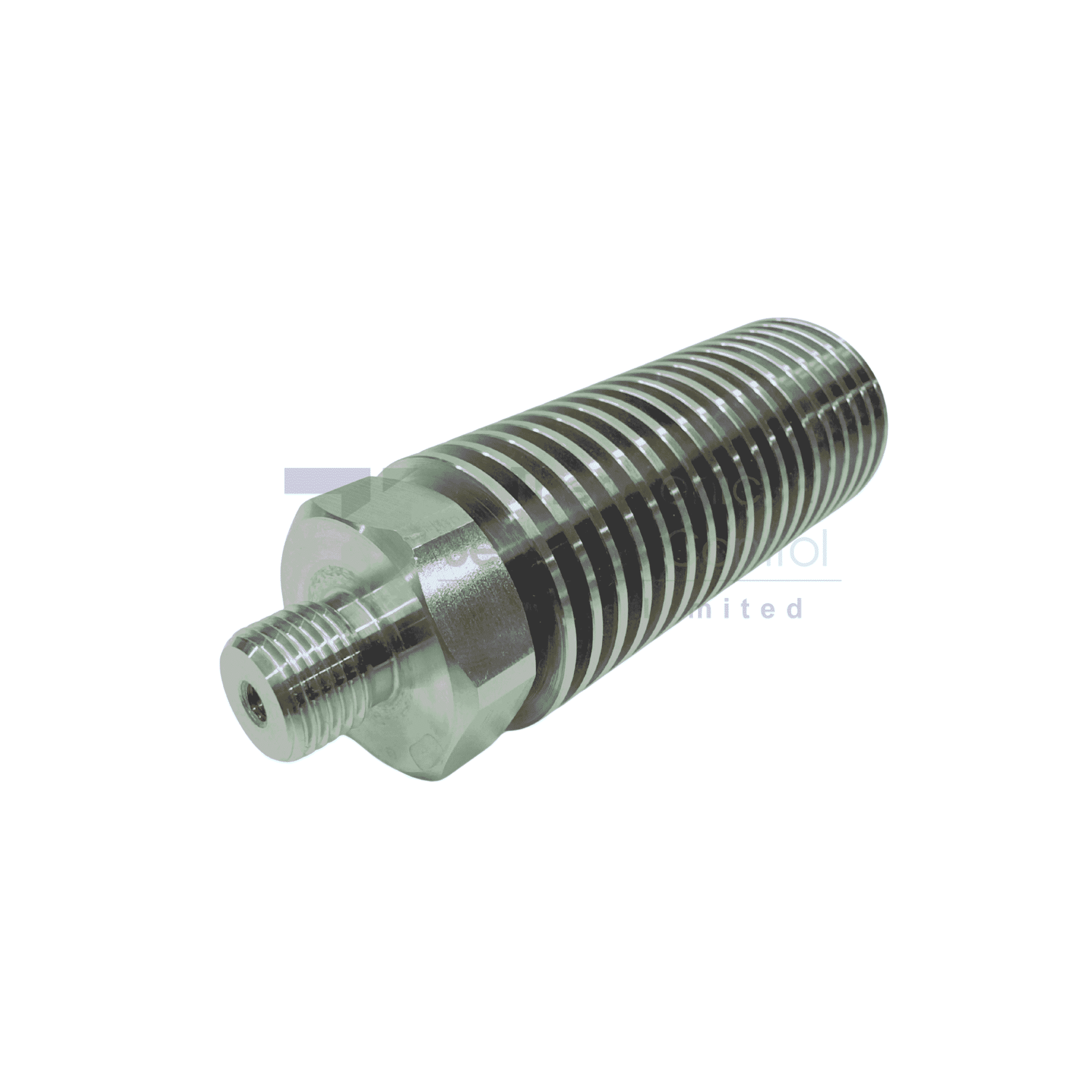

Flush Type Pressure Transmitter

Our Flush Type Pressure Transmitter is purpose-built to deliver operational clarity, process integrity, and long-term stability across applications where conventional sensing technologies often fall short. Designed with a flush, cavity-free diaphragm, this transmitter mitigates clogging, residue buildup, and media entrapment—making it a strategic fit for high-viscosity, crystallizing, or contamination-sensitive environments. Whether you’re managing adhesives, slurries, pastes, chemicals, food-grade materials, or sanitary production cycles, the architecture ensures seamless media contact and streamlined cleaning routines, unlocking measurable efficiency gains across your workflow.

At the core of the device is a high-accuracy sensing element engineered to deliver consistent, drift-resistant performance even under dynamic process conditions. Operators benefit from rapid signal stabilization, minimized downtime, and a reliable data foundation for automation, analytics, and quality compliance. Combined with its rugged stainless-steel construction, corrosion resistance, and resilience against temperature fluctuations, the transmitter maintains its performance integrity in both harsh industrial setups and hygienic production lines.

The installation profile is deliberately intuitive, reducing onboarding complexity and creating a plug-and-perform user experience that aligns with modern process automation strategies. The flush design supports CIP/SIP cleaning protocols, elevating hygiene standards while reducing maintenance cycles and unscheduled interventions. With flexible output options, wide pressure ranges, and compatibility across industry-standard process connections, the unit aligns seamlessly with existing infrastructure, enabling organizations to scale without architectural friction.

In short, the Flush Type Pressure Transmitter empowers teams to elevate measurement reliability, optimize operational cadence, and reinforce product quality across mission-critical processes. It’s a robust, future-ready solution engineered to meet the rising expectations of today’s industrial ecosystem—where precision, hygiene, and uptime are non-negotiable.

- Description

- Reviews (0)

Description

Our flush-type pressure transmitter delivers precision benchmarking through a seamless, cavity-free sensing interface engineered for high-viscosity and contamination-prone media. Its robust construction, rapid signal stability, and streamlined maintenance profile empower operators to elevate process reliability, ensure compliance, and drive consistent performance across mission-critical industrial environments.

Our Flush Type Pressure Transmitter is purpose-built to deliver operational clarity, process integrity, and long-term stability across applications where conventional sensing technologies often fall short. Designed with a flush, cavity-free diaphragm, this transmitter mitigates clogging, residue buildup, and media entrapment—making it a strategic fit for high-viscosity, crystallizing, or contamination-sensitive environments. Whether you’re managing adhesives, slurries, pastes, chemicals, food-grade materials, or sanitary production cycles, the architecture ensures seamless media contact and streamlined cleaning routines, unlocking measurable efficiency gains across your workflow.

At the core of the device is a high-accuracy sensing element engineered to deliver consistent, drift-resistant performance even under dynamic process conditions. Operators benefit from rapid signal stabilization, minimized downtime, and a reliable data foundation for automation, analytics, and quality compliance. Combined with its rugged stainless-steel construction, corrosion resistance, and resilience against temperature fluctuations, the transmitter maintains its performance integrity in both harsh industrial setups and hygienic production lines.

The installation profile is deliberately intuitive, reducing onboarding complexity and creating a plug-and-perform user experience that aligns with modern process automation strategies. The flush design supports CIP/SIP cleaning protocols, elevating hygiene standards while reducing maintenance cycles and unscheduled interventions. With flexible output options, wide pressure ranges, and compatibility across industry-standard process connections, the unit aligns seamlessly with existing infrastructure, enabling organizations to scale without architectural friction.

In short, the Flush Type Pressure Transmitter empowers teams to elevate measurement reliability, optimize operational cadence, and reinforce product quality across mission-critical processes. It’s a robust, future-ready solution engineered to meet the rising expectations of today’s industrial ecosystem—where precision, hygiene, and uptime are non-negotiable.

Reviews

There are no reviews yet.